Non-Woven Bags printed. Initial print run (MOQ) of 1,000 pieces.

-

-

-

-

-

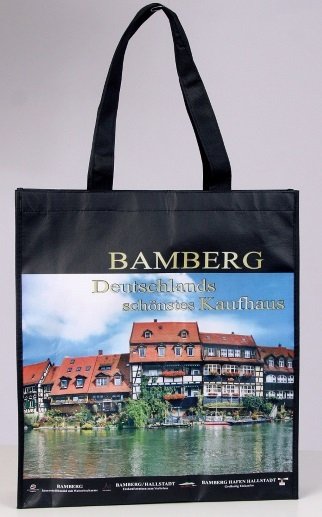

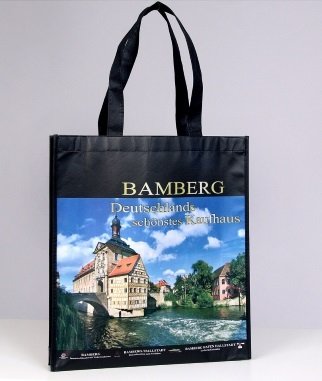

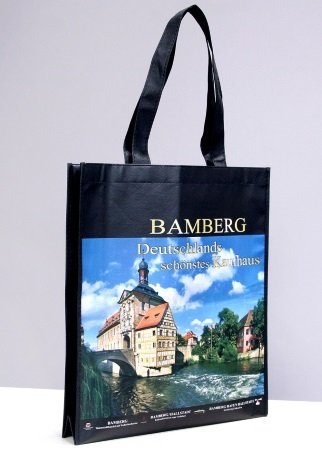

PP Non-Woven bag with lamination - Bamberg

Impression: 10.000 pieces

Size: 38 x 42 x 10 cm + 3 cm (width x height x depth + fold over)

Material: 80 g / m² PP Non-Woven laminated with BOPP Matte Film 30 g / m (total 110 g / m²)

Printing: rotogravure engraving 5 color CMYK and white paint; the two front sides of the bag have different motifs

Gravure printing cylinder: included

Handles: Two carrying straps same PP Non-Woven - but uncoated, double layered - stitched on both edges of the longitudinal sides of the belt. The four ends are sewn on the inside edge of the fold over, the top of the bag body; total length 2 x 60 cm, width 2.5 cm.

Work out: stitched as exclusive PP Non-Woven bags. On the edges of the side gussets a revolving braid sewn closes the edge endings. A fold laterally in the middle of side gussets, second folds middle of the bottom.

PP Non-Woven bags or cotton bags.

What should I take or print?

Among the various textiles cotton has definitely benefited the notoriety and is often mentioned as the first.

Cotton is a renewable resource. This makes it sympathetic. The prejudice to be environmentally friendly adheres to it.

Non-Woven we know though, often have to do with it. But we do not know much about Non-Woven.

Not rarely we have this fabric lying in our hands. Or the Non-Woven fabric is on our skin. In general, we have no use name ready for this fabric: Non-Woven. The Non-Woven fabric made of PP, PE or PET (for example, from used PET bottles). We do not bring in connection with this textile.

During our customer consultation, after all price comparisons with bagobag team the cheaper Non-Woven bags are quite often ordered in the end or - if you are in a hurry - paper bags with printing. Printed bags in Non-Woven textiles have a reliable price advantage over printed cotton bags. The decisive factor is not the sewing or the country of origin of the bags or lack of fairness in production terms, but the world market price of the material.

Sewing, printing, and forwarding tariffs go under standards. Their costs are the same for both types of bag in principle and thus negligible for this comparison.

Quality of Non-Woven bags. Tensile strength, durability.

What should I know?

On the quality of the bag Non-Woven bags, the material thickness has immense influence. If you select the material too thin for price reasons, it seems cheap and rips out under rigorous conditions.

Bags made of thin fabric are never durable. Bags with a thickness of less than 80 grams per square meter disappoint quickly. The lasting impression of promotional products is then calculated disappointment rather than the feeling of having been blessed. For the promotional products buyers therefore offers bagobag bags Non-Woven fabric on the first place from a grammage of 80 g/m².

What strength or which grammage should I order for my purpose?

For the fair bags, promotional bags, gym bags, Non-Woven drawstring pouch bags, the giveaways in large quantities, you are welcome to use material with 80 g/m². Unless you want to extremely prolong the use of the bag. If you want to be exclusive in the promotion or classy and want to be clearly distinguished from the competitor - then order the strength of 100 g/m².

For souvenir bags or promotional bags for city marketing and tourism we recommend a material with thickness of at least 100 g/m² or more, particularly if you opt for an uncoated Non-Woven bag.

Accountant’s bags and briefcase bags made in Non-Woven Accountant’s bags and briefcase bags made in Non-Woven for the round-trip transportation of file folders should be made for a lasting good impression of material with 120 g/m² or 150 g/m². We like to build you a bottom plate as well as a solid base reinforcement in the bags. To install reinforcement in the edge of the turnover bag is always a tight range in the opening form.

Shopping bags and tote bags in Non-Woven require a higher stability through material thickness. Opt for a grammage of 120 g/m² or 150 g/m².

Non-Woven bags with zipper, for example: cosmetic bags, sports bags, ball bags, you should not conceive of lesser thickness than 100 g/m².

My Bag: natural fiber or synthetic fiber?

What is better for me?

Food, medicine, cosmetics - Non-Woven synthetic fibers are fat,water-resistant and hygienic.

Cotton and pollutants. Most cotton is produced in conventional agriculture. Although the conventional cotton bag has quietly the image of being environmentally friendly, the cotton is in fact not - if the cotton is not expressly derived from organic production.

On closer inspection, however, a third-world problem is both in agriculture and in the textile production recognizable (water consumption, food competition, wage dumping). Due to intensive cultivation, such as the cotton plants and general pollution unfortunately lead to residues in natural raw materials such as cotton, jute or hemp. Plastic fibers contain no residue from pesticides, fertilizers or other environmental toxins. Cotton fibers are natural fibers and without chemical treatment not resistant to grease, rain or dirt. Permanent Non-Woven tote bags have exactly this advantage - even without being treated inside or outside or be laminated.

Standing in the rain. With the bag. The cotton bag absorbs moisture and passes it to the bag contents - even if you just place the bag on a wet surface. In the rain, the consumer is better off with a Non-Woven bag. An uncoated Non-Woven bag has indeed not completely closed surface and allows after some time due to moisture

Although an uncoated woven bag system has no completely sealed surface, non and after a time may transmit moisture - because the synthetic fibers do not sucks the moisture from the environment - however, this happens much later than in a cotton bag. The consumer is in a rainy world better off with a Non-Woven bag.

Non-Woven textile fabric colors

The choice of colors is greatest at 80 g/m². Here you will find high probability even your company colors or color. Best: Let us know your preferred color in Pantone and we will make a proposal. In the higher weights, the selection is sadly less. If you order quantities of about 100,000 bags, we can dye the exact color you want, but it needs some more time.

Recycling. Cotton bags or Non-Woven bags?

Which bag is better because in the end in the recycling?

In the EU, at least in the German speaking countries, there is a very reliable well-developed plastic recycling and material cycles. These guarantees: Each plastic article will give you, whether as a fiber or in another form, encounter later. Non-Woven is no longer wasted today because recyclable plastic money. At the end of the life cycle are Non-Woven bags back to a well-utilizing recyclable material.

You order from us plastic bags Non-Woven and if after finishing life time Non-Woven bags will be properly disposed of after the last use (for example yellow container), then the value of recovered substance cycle begins after plastic recycling again - like spring follows winter. So this material has not need to be in its substance compostable waste.

Conversely, if a cotton bag has done its work, it ends up in municipal waste, is not sorted out as organic fiber and recycled, but is generally burned with everything else as residual waste.

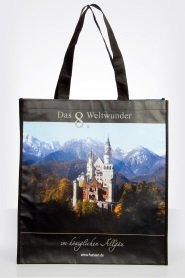

PP Non-Woven bag with lamination - BayerDescription: PP Non-Woven bags Impression: 2,000 pieces Format: 40.5 x 36.5 x 9.5 cm + 3 cm (width x height x depth + border perimeter) Material: 80 g / m² PP Non-woven with laminated BOPP film glossy 30 g / m² (total 110 g / m²) Printing: Gravure 4-color 100% printing surface Handles: 2 loops, length 2 x 70 cm width ca. 2, 5 cm with push button |

Offer No. 2014 - 9415 & 5338 Füssen - laminated PP Non-Woven bags, delivery on pallets

Impression: 10,000 pieces

Format: 38 x 42 x 10 cm + approx. 3 cm (width x height x depth + edge cover)

Material: 80 g / m² PP non-woven with laminated BOPP film matt 30 g / m² (total 110 g / m²)

Printing: Engraving rotogravure 5/0-color CMYK and opaque white

Gravure printing cylinder: inclusive

Handles: Two loops the same PP non-woven, sewn double-layer on the Pocket 2 x longitudinal stitched, length 2 x 60 cm, width approx. 2.5 cm

Processing: As an exclusive PP non-woven bag sewn, on the short sides a circumferential binding tape sewn on as a conclusion, on the center side a fold, in the middle in the middle a fold.

Templates: Customer delivers ready-to-print PDF data

Packaging: Handy and transport-safe packed in cartons, on pallets

Shipping: Free house (one address) Bamberg area, duty paid (DDP), curb or ramp

Pattern production: If desired plus 180, - € incl. Shipping (if the print motif is not changed again), delivery time approx. 2 - 3 weeks

Delivery Date: Approx. 12 weeks from print data release or sample release (by appointment)

Versatile reusable packaging made of PP Non-Woven

Those who opt for a tote bag in non-woven, receive a cost-effective and environmentally friendly quality product.

Here, the trendy non-woven bags are excellent for advertising, is at last not in a form of regular thread and during manufacture hot poured into a template and as a cast and after heat dissipation not as as they can be full area printed and finished in your desired size. The material is rain-resistant and recyclable.

In equipping your reusable bag ideas are boundless: Combination of different materials, interior coating, lamination and multicolored printed fabric, different closures and edgings.

Even in very small print runs of 500 pieces we produce customized for you, custom printed promotional tote bags non-woven at a very attractive unit price. Due to the durable quality your business gets a great advertising effect for a small price: Any high quality tote bag or shoulder bag carries your logo for years – in route to elongate promotion.

In the advancement of production you can request to an own 1:1 sample production. We will then produce in originally mass production patterns, using same machinery, your customized samples. So you will have one piece of the coming impression in your hands before mass production is done at all.

So you gain a sense of the pre-supplied quality and play safe. After order confirmation, we need about 40 days for your promotional bags production.

For special requests, we are happy to advise you by phone or by e-mail. We can show you by pics or sample consignment some other similar customized produced bags out of our production focused to your requested parameters and geared to your needs out of our best production terms.